Smarter, Leaner, and Faster: AI & ML in Supply Chain Optimization

The supply chain is no longer a back-office function—it’s a strategic asset that defines market leaders.

Amidst rising competition in the business turf, with every business striving to go global, and the ever-evolving customer expectations, traditional logistics models are struggling to keep up with the speed and precision that today’s modern business environment demands.

Modern supply chains today are shaped by rising complexity and uncertainty. Globalized networks, expanding product lines, shorter delivery windows, and elevated customer expectations have pushed traditional logistics models to their breaking point. What was once a linear process is now a multidimensional challenge—where speed, precision, and adaptability are critical to survival. Despite this heightened complexity, many organizations still rely on traditional supply chain management (SCM) systems—systems that are often siloed, slow to respond, and dependent on outdated, rule-based logic. These legacy infrastructures lack the agility to process real-time data or adapt to sudden disruptions, resulting in inefficiencies, stockouts, and missed revenue opportunities. Hence, a supply chain brain upgrade becomes a call of the moment.

This is where Artificial Intelligence and Machine Learning step in! Taking the centre stage, AI is fundamentally re-architecting the supply chain. Instead of relying on static rules and historical data alone, AI/ML systems analyze vast data streams in real time, recognize patterns, anticipate disruptions, and automatically recommend actions. The result? Agile, intelligent ecosystems that evolve continuously. AI-driven forecasting adapts to shifting demand. ML-powered logistics optimize routes on the fly. Inventory levels self-correct based on predictive models. With every transaction and sensor input, the system learns, getting smarter, faster, and leaner. In this blog, let us deep dive to understand how artificial intelligence and machine learning are taking the center stage and empowering businesses to have supply chains that think for themselves.

What is a supply chain?

The network of all the individuals, organizations, resources, activities, and technology involved in the creation and sale of a product, from raw materials to the end consumer

Artificial intelligence and machine learning at the helm of an intelligent supply chain

Today’s supply chains must be more than just connected—they must be intelligent, adaptive, and self-correcting. At the core of this evolution are data-driven technologies—Artificial Intelligence (AI) and Machine Learning (ML)—backed by a robust digital infrastructure. Together, they work in harmony to create a foundation for smarter planning, leaner operations, and faster execution.

Artificial Intelligence vs. Machine Learning: Similar Tools, Distinct Roles

AI and ML are often used interchangeably, but do they have similar or distinct functions? Understanding the distinction becomes essential for enterprises to initiate effective implementation:

Artificial Intelligence (AI): It is the broader concept, where systems mimic human intelligence to solve problems, learn, and make decisions. In supply chains, AI can automate procurement, recommend inventory actions, simulate logistics scenarios, and provide real-time alerts.

Machine Learning (ML): It is a subset of AI focused on algorithms that learn from data without being explicitly programmed. ML models detect patterns—like seasonality or supplier performance trends—and adapt continuously, improving their accuracy over time.

For instance, AI might trigger an auto-replenishment order based on stock depletion, while ML refines the quantity ordered based on past consumption, forecast accuracy, and supplier lead times. Working in symphony, AI and ML enable decision-making at speed and scale, replacing static rule-based processes with dynamic, adaptive intelligence.

At this juncture, a point to ponder remains: without quality data, how smart can an AI be? Can it transform a traditional supply chain into supply chains that think for themselves without quality data? The answer is that data is the fuel that drives AI and ML’s efficiency.

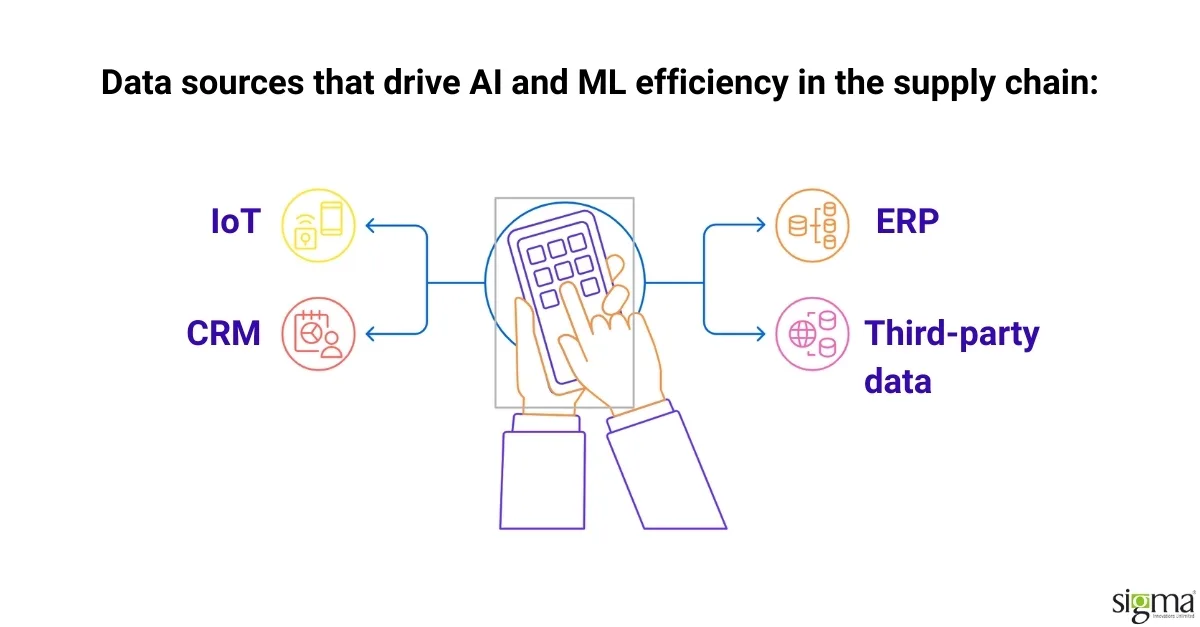

Data as the Fuel: Breaking Down Silos

No intelligence system can function without data. But most legacy supply chains operate in silos, where sales, procurement, logistics, and customer service maintain disconnected datasets. For AI/ML to work effectively, these silos must be broken, and data must be centralized, contextualized, and continuously refreshed. AI isn’t just smarter automation—it’s contextual automation. Its quality and accuracy depend entirely on the breadth, depth, and timeliness of data inputs. Here is an overview of key data sources that drive AI and ML efficiency in the supply chain:

IoT (Internet of Things): Smart sensors embedded in an enterprise’s infrastructure, trucks, machinery, and warehouses provide real-time data, critical for tracking assets and maintaining product quality.

ERP (Enterprise Resource Planning): Captures core business data—orders, inventory levels, supplier contracts, and financial metrics—that AI models use for forecasting and planning.

CRM (Customer Relationship Management): Offers insights into consumer behaviour, satisfaction scores, and sentiment analysis, enabling demand forecasting and service improvement.

Third-party data: Includes information pertaining to weather feeds, geopolitical events, financial markets, news, and supplier reliability indices. These external signals help AI models factor in macro risks and demand influencers.

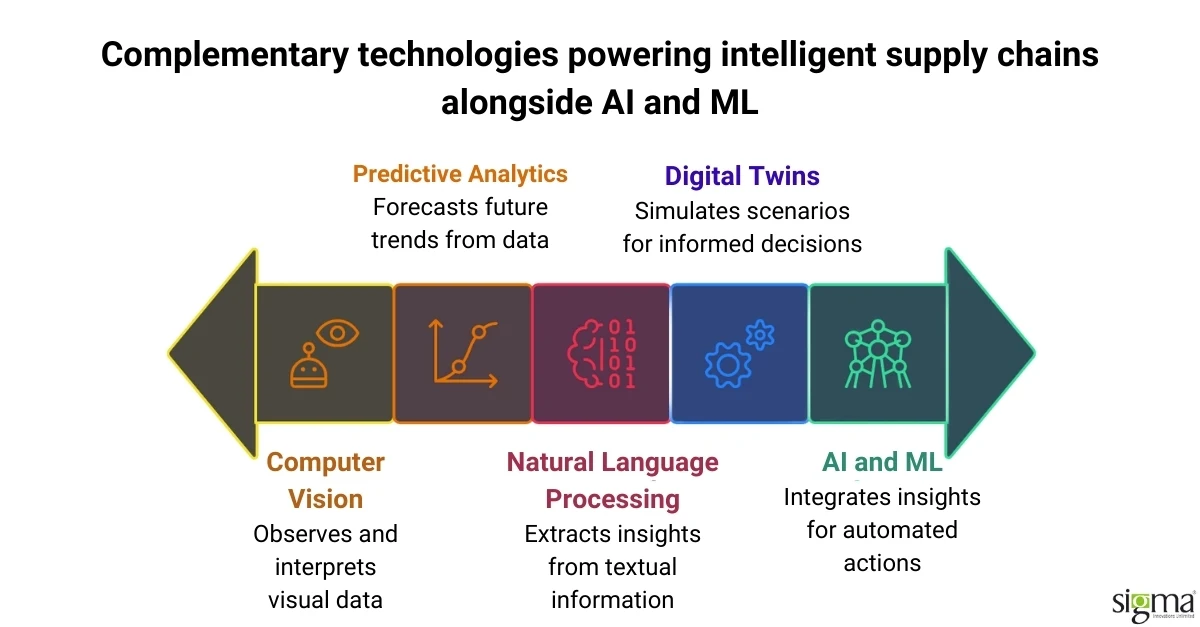

Stack of complementary technologies powering intelligent supply chains alongside AI and ML

Modern supply chains are no longer reactive networks—they’re intelligent ecosystems driven by AI and ML. These core technologies sense, learn, and adapt continuously, enabling real-time decisions and enterprise automation with AI across the value chain. But AI/ML don’t operate in isolation. A stack of complementary technologies works alongside them to supercharge visibility, foresight, and responsiveness.

Predictive analytics: From data to demand precision

Powered by AI/ML, predictive analytics turns historical and real-time data into accurate forecasts—enabling demand prediction, disruption alerts, bottleneck detection, and dynamic inventory and capacity planning. Ex: Predictive models powered by AI/ML enable businesses to forecast demand spikes during campaigns, ensuring optimal stock placement and reducing stockouts and excess inventory.

Natural Language Processing (NLP): Turning Text into Actionable Intelligence

Powered by machine learning, Natural Language Processing (NLP) brings unstructured text—like reviews, emails, and contracts into the decision-making process. It enables supply chains to detect shifting customer sentiment, identify quality issues early, automate compliance checks, and streamline service workflows. Ex: NLPs can help enterprises flag a spike in delivery complaints from a specific region, triggering a proactive logistics response before the issue escalates.

Computer Vision: A Watchful Eye for Smarter Operations

Computer vision, combined with machine learning, transforms images and video into actionable intelligence across the supply chain. It enables autonomous warehouse operations like scanning, sorting, and counting; automates quality inspections on production lines; and detects damage in packaging and transit in real time. Besides improving operational speed, it reduces human error and enhances safety in fast-moving logistics environments.

Digital Twins: To test scenarios and reduce risk

Powered by AI/ML, digital twins are dynamic virtual models of real-world supply chain assets, such as fleets or distribution centres. Continuously updated with real-time data, they simulate operations, predict disruptions, and optimize decisions. From forecasting demand surges to planning maintenance and rerouting logistics, ML-trained twins enable organizations to test scenarios and respond proactively. It enables businesses to make informed, risk-free decisions before real-world issues impact their performance.

AI and ML, and Connected Intelligence in Action

When AI, ML, and supporting technologies work together, they power a self- optimizing supply chain, where data flows in real time, models predict outcomes, and automation acts instantly, keeping human teams focused on strategy and exceptions. From reactive to predictive, from fragmented to intelligent. That’s the AI/ML-enabled supply chain.

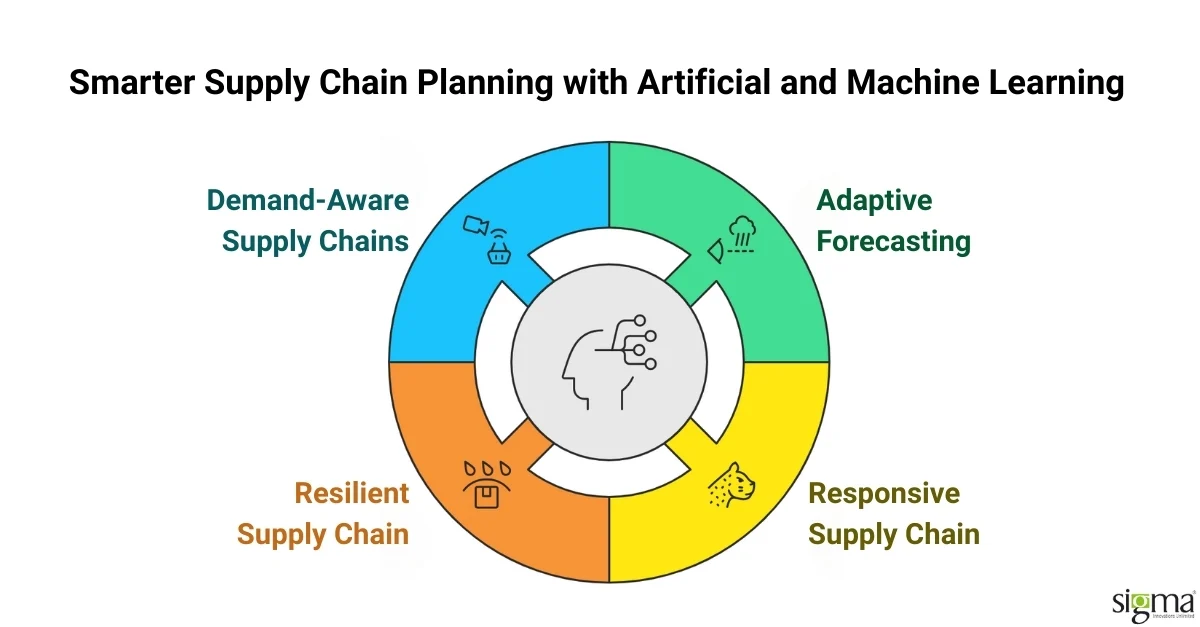

Smarter Supply Chain Planning with Artificial Intelligence and Machine Learning

Gone are the days when forecasting in supply chain management was about looking at past sales and projecting future demand. Today, the pace and volatility of global commerce demand real-time, adaptive, and predictive planning—and that’s exactly what AI and ML bring to the table. AI-powered demand planning enables organizations to move from rigid, calendar-based forecasting to dynamic, responsive models that reflect what’s happening in the real world right now.

Adaptive AI-Driven Demand Forecasting—Agile Supply Chain

Traditional forecasting methods often rely on historical sales averages and fixed assumptions. But those models struggle when demand becomes erratic or influenced by external factors like weather, global events, or regional campaigns. AI-driven forecasting engines analyze real-time signals—like sales, promotions, weather, and sentiment—to detect patterns and trends faster than human analysts. They continuously update demand forecasts, enabling accurate stocking, lower inventory costs, and reduced risk of overstock or stockouts.

ML-Powered Forecasting—Responsive, Resilient Supply Chain

One of the key advantages of ML models is their ability to learn over time. AI/ML-powered systems don’t just automate—they continuously learn and adapt across the supply chain. They respond in real time to seasonal demand shifts, detect viral trends, and react to disruptions like supply shortages or port congestion without manual reprogramming. Unlike static, rule-based tools, machine learning evolves with every data point, making it ideal for today’s volatile markets and complex supply chain environments. The real advantage? The more data these systems process, the smarter and more resilient a supply chain becomes, turning unpredictability into a competitive edge.

AI-Powered Demand Sensing: Demand-Aware Multi-Channel Supply Chains

In a multi-channel world, demand isn’t uniform. What’s trending on an e-commerce platform in one city may not reflect what’s selling in physical stores elsewhere. Traditional planning often misses the mark when it comes to these micro-trends. AI-powered demand sensing transforms supply chain responsiveness and precision. By capturing real-time sales signals across all channels—retail, D2C, e-commerce, and third-party sellers—it identifies granular shifts in demand and regional variances. This enables faster reactions to localized promotions, events, and competitor actions, while supporting channel-specific inventory allocation and pricing strategies. Owing to this, businesses gain a more agile, demand-aware supply chain, avoiding generic planning, reducing excess inventory, and driving higher margins through targeted, data-driven decisions.

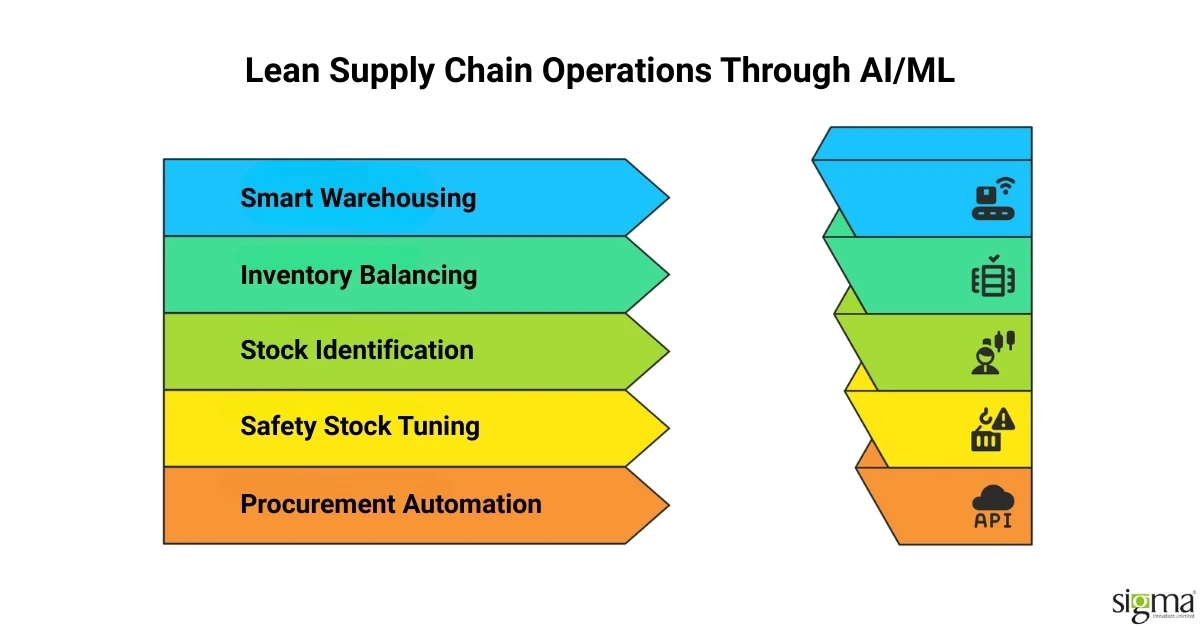

Lean Supply Chain Operations Through AI/ML-Driven Inventory and Resource Optimization

Lean supply chains are no longer just about cutting costs—they’re about precision, adaptability, and intelligent resource orchestration. With AI and ML, B2B companies can achieve the elusive balance between service excellence and operational efficiency by fine-tuning inventory flows, minimizing waste, and optimizing procurement in real time. How are AI and ML enabling a lean supply chain?

Smart Warehousing and Inventory Flow Balancing with AI

Warehouses are becoming nerve centers of agility, not just storage facilities. AI and sensor-based automation are transforming warehouse management into a data-rich, real-time operation that responds dynamically to demand, space constraints, and workforce availability. Smart algorithms optimize slotting by placing high-frequency items closer to packing zones, while load balancing redistributes inventory across locations based on localized demand. AI also predicts capacity needs, helping optimize layout, workforce planning, and space usage. Autonomous robotics, including automated guided vehicles and cobots, streamlines manual tasks, enhancing efficiency and accuracy at scale.

Identifying Excess, Obsolete, or Slow-Moving Stock with ML

One of the silent killers of supply chain efficiency is excess inventory, items that sit idle and consume warehouse space, capital, and operational overhead. Traditional tools often rely on static days-of-inventory calculations. ML brings clarity and speed to this challenge.

ML capabilities are driving smarter inventory decisions across the supply chain through proactive, data-driven insights. Machine learning algorithms detect slow-moving items by recognizing patterns across promotions, regions, and seasonal trends. Lifecycle analysis monitors product inventory stages and alerts for early signs of obsolescence.

Intelligent alerts prompt teams to bundle, discount, or relocate stock before it becomes deadweight, while heat maps visualize inventory aging across zones, product lines, or vendors, recommending and prioritizing clearance actions. Owing to this, enterprises can improve inventory turnover, reduce carrying costs, and ensure stronger cash flow, vital for optimizing working capital across the supply chain.

Fine-Tuning Safety Stock Levels Dynamically with AI-Driven Predictive Modeling

Static buffer strategies often fail, either inflating inventory or risking stockouts. AI/ML-powered predictive modelling solves this by dynamically fine-tuning safety stock levels based on real-time signals. Models continuously recalibrate buffers in response to demand shifts, supplier reliability, and transport lead times. High-risk items are placed in “smart zones” within warehouses for faster replenishment, while disruption-aware modelling adjusts stock levels proactively during events like strikes or natural disasters. Besides improving on-time fulfillment, it reduces excess inventory, paving the way for a more resilient, confident supply chain that will operate glitch-free under pressure.

Strategic Procurement Automation with AI

AI’s ability to make fast, intelligent decisions is helping the supply chain evolve from mere transactional purchasing to strategic supply orchestration. AI is transforming procurement into a proactive, data-driven function within the supply chain. It automates purchase orders based on forecasted demand, usage trends, and stock thresholds, while recommending the best-fit suppliers using metrics like delivery reliability, cost performance, and responsiveness. AI also flags potential sourcing risks—such as delays, quality issues, or geopolitical disruptions—enabling timely mitigation. AI also integrates the procurement aspect of the supply chain with demand planning, aligning purchases with marketing and sales calendars to ensure the timely availability of materials for key campaigns. Owing to this, businesses can have faster procurement cycles, stronger supplier relationships, smarter sourcing decisions, and fewer operational hurdles.

Overall, what is the bigger picture? From “Just Lean” to “Intelligently Lean Supply Chain.” Traditional lean practices focused on removing waste. AI and ML elevate that principle to the next level by continuously learning, adapting, and optimizing operations, without sacrificing flexibility or service. A leaner supply chain no longer means running on the edge. It means running smart, where every resource is right-sized, just-in-time, and just-in-case when needed.

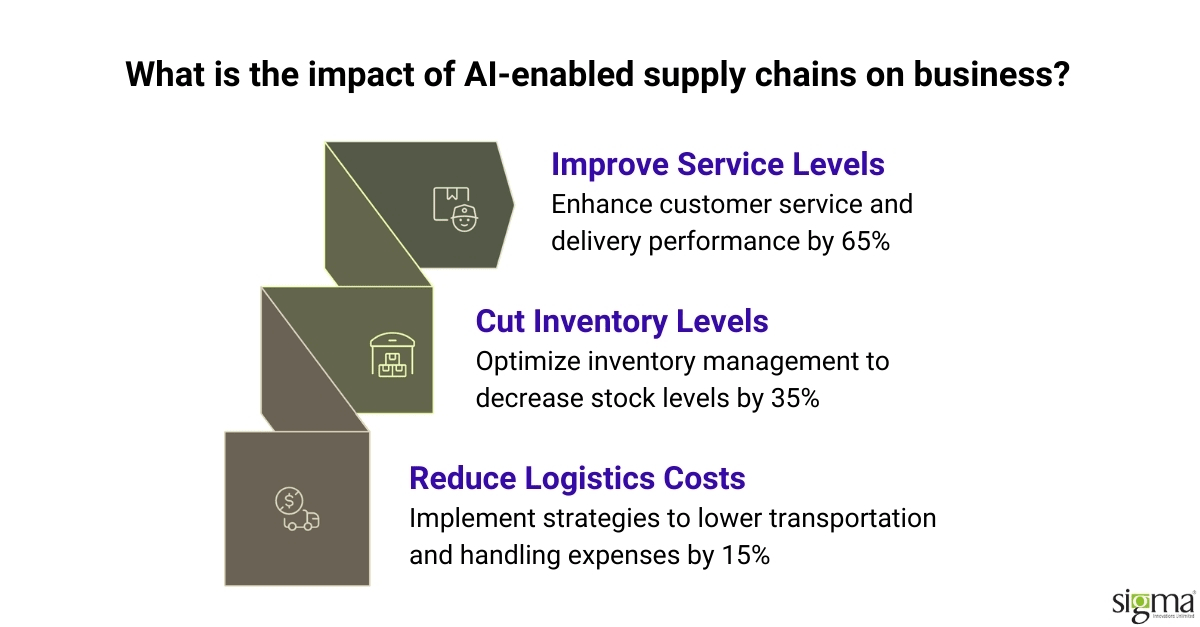

The impact of AI/ML-driven intelligent supply chains on businesses

AI and ML are transforming supply chains from cost centers into strategic growth drivers. By enabling real-time forecasting, adaptive planning, and autonomous operations, intelligent supply chains reduce waste, lower costs, and improve service levels. Businesses gain enhanced visibility, faster response to disruptions, and the agility to meet changing customer demands—ultimately improving margins, resilience, and competitiveness. Let us understand how AI drives enterprise transformation.

Source: McKinsey

Improved Forecast Accuracy

AI/ML models analyze real-time and historical data to more precisely predict demand, minimizing stockouts, reducing excess inventory, and enabling enterprises to plan operations and execute them with confidence.

Faster, Smarter Decision-Making

With real-time insights, businesses can quickly adapt to market shifts and disruptions, minimizing downtime and revenue loss.

Greater Operational Efficiency

Intelligent automation in the supply chain cuts manual effort, streamlines processes, and lowers operational costs—freeing up the bandwidth of teams in an enterprise for higher-value tasks.

Increased Agility

Adaptive planning in the supply chain helps businesses pivot quickly to evolving customer needs, supply disruptions, or new market opportunities.

Enhanced End-to-End Visibility

Predictive analytics and connected data improve supply chain transparency, enabling better control, traceability, and planning accuracy.

Risk Reduction and Disruption Management

AI identifies early warning signs of delays, shortages, or failures in a supply chain, enabling proactive, preventive action before issues escalate.

Higher Customer Satisfaction

Accurate fulfillment and product availability translate into faster delivery, fewer stockouts, and helping businesses strike the right chord with their clients. and further enhancing customer loyalty.

Sustainability Gains

Optimized inventory, routing, and demand planning in supply chains reduce waste, lower emissions, and support enterprises in fulfilling ESG goals.

Stronger Competitive Advantage

AI-enabled supply chains deliver speed, intelligence, and resilience—helping businesses stay ahead of reactive competitors.

Read the success story: Automating Ticket Resolution with AI-Powered Resolvify++

Where Theory Meets Practice: AI/ML in Action: Real-World Intelligent Supply Chain Use Cases

The benefits of AI consulting for large businesses are plenty! It bestows enterprises with greater agility, resilience, and competitive advantage through smart, data-driven supply chain operations. Across industries, AI and ML are not just supporting supply chains—they’re redefining them. What was once reactive, manual, and opaque is now predictive, automated, and intelligent. Use cases may differ, but the value delivered is steady.

Smarter Retail Supply Chains with AI/ML

From Forecast to Fulfilment—Intelligence at Every Step: Retail businesses are leveraging AI and ML for intelligent supply chains for accurate demand forecasting, smart replenishment, personalised fulfilment, and predictive returns management—driving efficiency, reducing waste, and enhancing customer experience.

Intelligent Manufacturing Supply Chains with AI/ML

AI/ML-Driven Planning, Optimization, and Risk Mitigation at Every Step: AI/ML empowers enterprises with manufacturing supply chains to operate with agility. Machine learning detects equipment issues early to prevent downtime, while dynamic production planning adapts to order changes and resource availability. AI also helps manufacturing companies to optimize inventory levels by aligning raw materials and finished goods with real-time demand signals. Additionally, supplier risk models flag potential disruptions, ensuring smoother, uninterrupted production flows.

Fraud Detection in Fintech Supply Chains with AI/ML

Proactively Identify Anomalies and Prevent Losses: AI/ML is revolutionizing fraud detection across fintech-enabled supply chains. By analyzing patterns in transaction flows, invoices, purchase orders, and logistics data, AI models can quickly identify anomalies and suspicious behavior, flagging potential fraud before it impacts operations. AI/ML-powered supply chains allow businesses in trade finance to verify the authenticity of documents and detect duplicate or inflated invoices.

Challenges and Considerations of AI/ML-Driven Supply Chains

While AI/ML promise smarter, leaner supply chains, successful implementation requires careful navigation of key challenges:

- Data Quality & Integration: AI is only as good as the data it learns from. Inconsistent, siloed, or incomplete datasets can compromise accuracy and effectiveness. Seamless integration across ERP, IoT, CRM, and legacy systems is essential.

- Legacy Infrastructure & Change Management: Many organizations struggle to retrofit AI into outdated systems. Aligning tech upgrades with cultural change and upskilling is critical for adoption.

- AI Model Transparency & Explainability: Supply chain decisions impact cost, compliance, and customer satisfaction. Black-box AI models can undermine trust unless their recommendations are explainable and auditable.

- Cost vs ROI: Upfront investment in AI tools, infrastructure, and talent can be substantial. ROI often comes from long-term gains—better forecasting, reduced waste, and faster decisions.

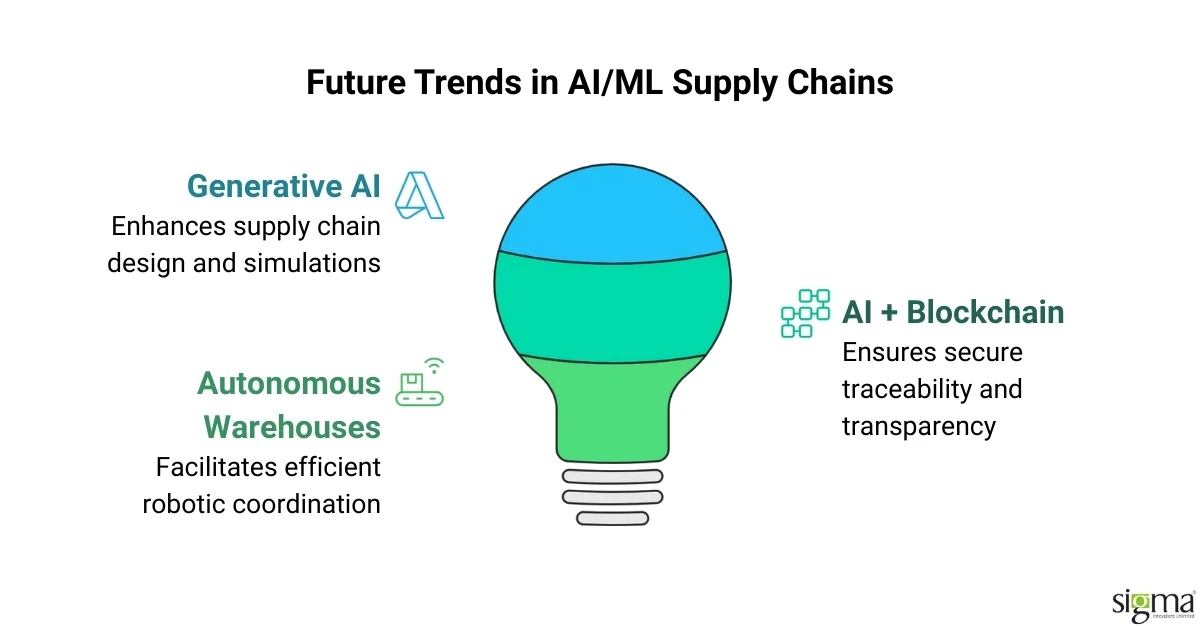

The Road Ahead: Trends Shaping the Future of AI/ML Intelligent Supply Chains

As AI/ML matures, supply chains are evolving from linear pipelines into intelligent, interconnected ecosystems. The future of AI-driven supply chains—they won’t just move goods; they will sense, learn, decide, and evolve on their own. Here’s what’s on the horizon:

Generative AI in Supply Chain Design & Simulations

GenAI enables rapid modelling of new supply chain configurations, network designs, and response strategies. It can generate optimized plans, simulate disruptions, and propose alternatives faster than traditional tools.

AI + Blockchain for Secure Traceability

Combining AI’s pattern recognition with blockchain’s tamper-proof records enables end-to-end visibility—from raw materials to last-mile delivery—boosting trust in compliance, sourcing, and sustainability claims.

Autonomous Warehouses & Robotic Coordination

AI orchestrates fleets of robots, drones, and AGVs (automated guided vehicles), enabling 24/7 warehouse operations with real-time adjustments based on demand, labor availability, or space utilization.

Achieving Supply Chain Zen with AI and ML

The shift toward intelligent automation paves the way for “Supply Chain Zen”—a state where operations achieve harmony, balance, and responsiveness. It’s not just about efficiency; it’s about flow. Imagine a supply chain that senses demand, adapts to change, self-corrects in real time, and collaborates across functions effortlessly. Supply Chain Zen is the endgame: a dynamic, resilient, faster network where intelligence is embedded at every node, and decisions are made with clarity and speed.

Sigma Infosolutions: Bridging Strategy and Execution in AI/ML-Enabled Supply Chain Innovation

The journey toward AI-driven intelligent supply chain—where balance, intelligence, and adaptability define operations—requires more than technology. It takes a strategic partner that can guide transformation across both systems and culture. This is where Sigma Infosolutions makes a tangible difference. As organizations shift from fragmented legacy systems to AI/ML-powered ecosystems, Sigma, with its ai consulting services and ai implementation services, acts as a catalyst for scalable, sustainable, and smart supply chain transformation.

From Vision to Value: Sigma’s Role

Sigma Infosolutions helps enterprises translate the promise of AI into real, measurable impact. The role spans across the full digital supply chain maturity curve:

AI strategy for businesses, ML solutions & roadmapping

We align AI initiatives with an enterprise’s business objectives, identifying where intelligent automation, predictive analytics, or autonomous workflows will generate the highest ROI.

Smart Platform Engineering

Sigma builds and customizes AI-powered platforms that seamlessly integrate with ERP and other core systems, ensuring interoperability and future readiness.

Modular, Composable Architecture

Sigma’s artificial intelligence and machine learning solutions, and AI integration services empower businesses to avoid vendor lock-in with scalable, component-based solutions that evolve with supply chain necessities, like scaling to new markets, product lines, or partners.

Whether it’s a FinTech network managing digital vendor flows, or a manufacturing leader orchestrating just-in-time precision, a retail brand optimizing omnichannel fulfilment, or an industry-specific AI model development, Sigma’s Artificial Intelligence Development Services delivers AI-infused solutions tailored to an enterprise’s unique supply chain challenges.

Wrapping up

The global AI/ML in the supply chain market is projected to reach USD 157.6 billion by the end of 2033, with a remarkable CAGR of 42.7%! What does this mean for businesses? Enterprises are incorporating AI/ML into their supply chains to make them smarter and more effective and stay ahead of the curve. If you are a business vying to latch on to AI-driven intelligent supply chains, it is the right time!

Are you looking to gain a competitive edge with AI-driven intelligent supply chains? Opt for Sigma’s AI Development Solutions right away and achieve your objectives.